Olyset Net

Sumitomo Chemical

Solution Overview & Benefits

Traditional mosquito nets require regular dipping in insecticide to maintain effectiveness in repelling mosquitoes, as insecticide is dislodged during regular use and washing. There are also practical problems in re-treating nets in remote areas, a long way from the urban centres where stocks of insecticide and trained advisors are located.

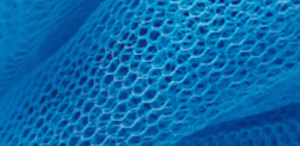

Sumitomo Chemical engineers set about developing the first net that does not need this constant re-treatment. The process begins with insecticide-impregnated beads, which are extruded into fiber and warped onto bobbins to be knitted into rolls of netting.

The netting rolls are cut into sized panels which are machine-stitched into the nets themselves. Chemical and physical checks are made before the nets are sent for delivery by land, sea and air. Because the insecticide is incorporated within the fibers, Olyset Nets are truly ready-to-use, long-lasting and never in need of treatment. Washing does not diminish their effectiveness, and they have been shown to still repel mosquitoes seven years after initially being put into use.

Key features:

-Guaranteed to last at least five years. Research indicates that a seven-year life is often achievable. -Tough – Olyset Net uses polyethylene technology that makes the net stronger and more tear resistant than polyester nets. -Controlled release technology – unlike polyester nets, the insecticide in Olyset Net is contained within the fibre, not coated on the outside. This technology provides a slow release of the active ingredient which continues to control mosquitoes for more than five years. -Quadruple insecticide effect on mosquitoes – bite inhibition, repellency, knockdown, kill. All contribute to protection from biting mosquitoes and other insects.

History & Development

Sumitomo Chemical pioneered a technology to develop a net that effectively prevents mosquito biting, lasts for a long time and resists both washing and tearing. Olyset Net incorporates the insecticide permethrin into the actual fibers of the net, and releases it slowly over a number of years.

Olyset Net passed the rigorous testing procedure known as WHOPES (World Health Organization Pesticide Evaluation Scheme). This involved extensive laboratory and field studies held under scientific scrutiny, and a commitment to quality assurance through the publication of agreed specifications. Olyset Net was the first LLIN to pass WHOPES and earn WHO’s recommendation.

Olyset Net is a crucial tool in the fight against malaria - and was the first WHO-recommended LLIN to be manufactured in Africa, where a child dies from malaria every 30 seconds. Production in Africa began in 2003 when Sumitomo Chemical provided a royalty-free technology license to A to Z Textile Mills in Arusha, Tanzania. Tanzanian production was further expanded in 2008 when Sumitomo Chemical celebrated the official opening of a 50:50 joint venture factory, expanding our partnership with A to Z in East Africa. In 2009, Olyset Net production capacity in Arusha will exceed 29 million nets a year -- more than half of the global Olyset Net output.

In June 2009, Sumitomo Chemical opened an Olyset Net stitching factory in Kombolcha, Ethiopia, which will produce 3 million Olyset Nets in its first year of operation. Read more.

Olyset Net is a part of Sumitomo Chemical's corporate social responsibility program, and our commitment to helping the people of Africa is recognized internationally. Olyset Net production in Tanzania employs more than 5,000 people, and supports over 25,000 people in the vicinity of the factories. Additional local sewing facilities are currently planned in Malawi and Uganda.

Availability

Publicly available: yes

Countries where available: Worldwide

Available online: yes

Additional Information

Updates

If you are aware of any updates to the Olyset Net project please complete the form or send an email to [email protected]

Need help finding solutions that respond to your unique development challenges? Apply through our Project Accelerator service or Contact us directly for needs-based project consulting.